Understanding Distillation process

Steam Distillation

"Our essential oils are extracted by steam distillation technique. Each raw material is sourced entirely in Cambodia. The team works closely with farmers who cultivate each raw material for us without third party involved to make sure there are no harmful chemicals added in the process. We also distill each and every oil by ourselves to ensure the purity of the oils we produce."

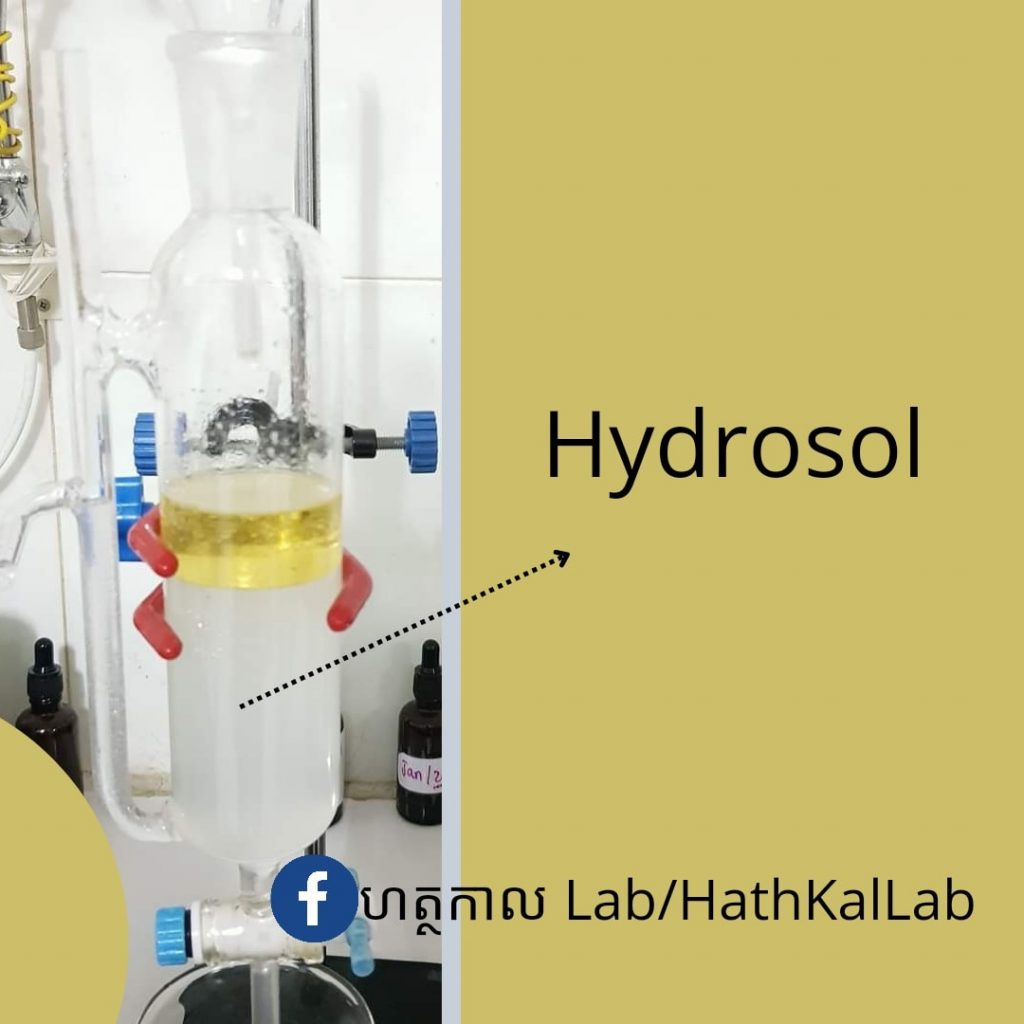

"There are several extraction methods; however, HathKal Lab believes Steam distillation is the most convenient method in terms of affordability, quality, and time. The most important point is there are no chemical substances required in the process. Water and oil molecules are transformed into steam through heat before being condensed back into liquid through condenser. At the end of the process, each oil requires filtration to become crystal clear before sales."

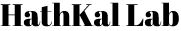

Shelf life of hydrosol is pretty unstable due to water content in the product which allows the bacteria to grow (shelf life only several days). Therefore, direct contact on the skin may be a problem. Therefore, our team is now working on technique to extend its shelf life and the safe packaging methods to prevent the growth of bacteria. If you are now using hydrosol, we suggest you frequently check whether the product has been spoiled by bacteria before spraying on the face. It is recommended that pregnant women discuss with doctor before using such product as well since it's very similar to essential oil, yet softer with water. This product can alter the hormone of pregnant women when conceiving. Natural products do not always mean "safe". It can be double edge sword if we don't understand them enough.

" Due to different density, essential oil and water can not mix. Although most essential oils are on top, some can also be at the bottom. The age of raw materials as well as the temperature used during distillation process are the factors changing the color of final products. "

Coconut Oil extraction

As long as coconut oil is extracted 100% from real coconut without any harmful chemical added, it is edible. In the market, producers have used so many terms to address their coconut oil such as virgin coconut oil, extra virgin coconut oil, cold process coconut oil, cold-pressed coconut oil etc. They are all "coconut oil". The terms are used to refer to its purity, but somehow they lead to confusion and misunderstanding among consumers. Virgin or Extra Virgin coconut oil which does not undergo more processing to reduce the coconut scent and flavor is "unrefined coconut oil". Cold process, hot process and cold-pressed coconut oil refer to the extraction techniques used to extract the oil. Generally, unrefined coconut oil is solid at room temperature and has strong scent and flavor. Meanwhile, "refined coconut oil" requires more processing to reduce the scent and flavor. In some cases, it is edible but in some cases, it is not depending on the substances added, which is used to preserve, to reduce scent, and lighten up the color. However, in Cambodia, unrefined coconut oil is the most convenient way to produce coconut oil since the country has abundant coconuts. Moreover, importing chemicals in the country is pretty costly. The most important point is we believe that it is the safest form of coconut oil.

FUN FACT: "All the techniques applied to extract the coconut oil intend to separate water out of the mixture because water is the culprit which spoils the product. Water is where bacteria grow! "

Hot Process Coconut Oil

Coconut milk is heated at high temperature to separate water out of the mixture. However, nutrients also can not survive in such high heat. Although this type of coconut oil can be preserved in long period of time, most people do not prefer it for consumption.

Cold Process Coconut Oil

Coconut milk is kept in clean environment untouched for days until the fermentation process separates the phases of coconut cream and water. The oil can later be filtered out of coconut cream. Although nutrients are preserved, water molecules can not be separated completely, which leads to product spoilage easily.

Cold-pressed coconut oil

Coconut meat is dried in dehydrator until becoming copra. Copra is pressed by hydraulic machine to get the oil. Then, the oil is filtered and bottled. The process takes 2 to 3 days. Final products can be preserved for up to 2 years without preservative added. However, machines are pricey!

Coconut oil has become a popular product used from head to toe. It is truly effective when it comes to skincare and haircare. However, consumption of coconut oil should be limited. So many sellers claim that Coconut oil helps combat the risk of heart disease caused by bad cholesterol. It's not true. Our body needs energy from two types of fatty acid: Saturated Fatty Acid (produced directly by the body) and Unsaturated Fatty Acid (got from foods, body can't produce it). Both are not bad, but too much of one thing is unhealthy. Coconut oil is full of saturated fats, which the body can already produce. Too much saturated fat can cause cholesterol to build up in your arteries (blood vessels). Saturated fats raise your LDL (bad) cholesterol. High LDL cholesterol increases your risk for heart disease and stroke. The key to stay healthy is to "Balance" what you eat.

Natural products can be double edge sword if without proper understanding. They are not always safe 100%. Therefore, the key to healthy lifestyle is "Balance".

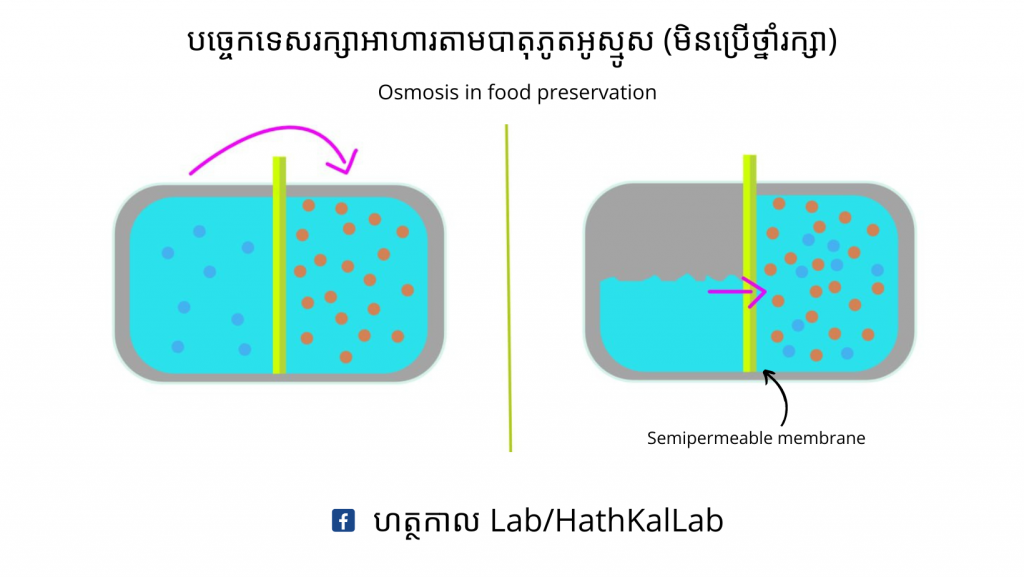

Osmosis in Food preservation

In some cases, producers turn to physical methods of food preservations instead of using preservatives. Osmosis is often applied in daily life by many people. Osmosis: solvent molecules pass from a solution of lower concentration to a solution of higher concentration through a semipermeable membrane. For example, you can preserve foods in concentrated salt and sugar or honey solution for longer period of time. Salt or sugar solution is concentrated. It means that water molecules inside the bacteria inevitably demand to go to the higher concentrated area. Without water, bacteria shrink and can not survive. We don't even need to use preservatives. HathKal Lab tries to turn to such physical methods to preserve our products because we care about your health.

The science of soap making